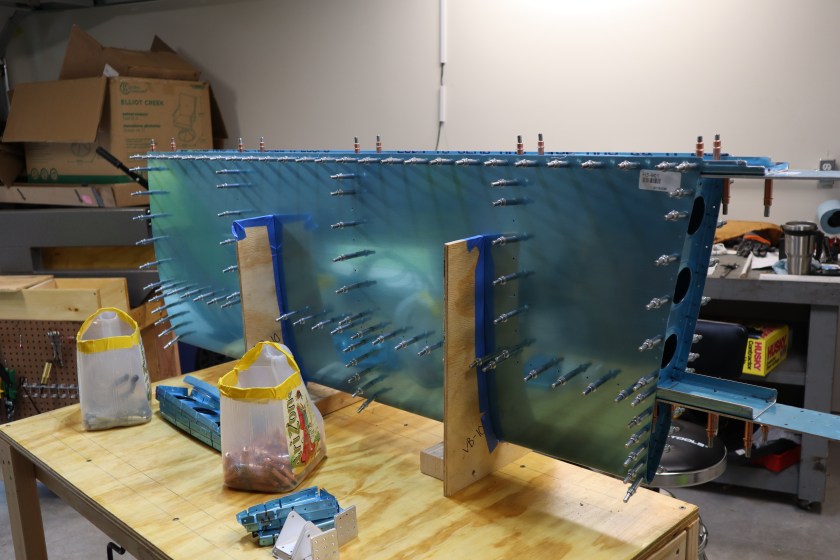

Just a quick picture of the horizontal and vertical stabilizers together before they were put into storage.

Category: Horizontal Stabilizer

Horizontal Stabilizer 3

After gaining experience on the vertical stabilizer, it is time to tackle the horizontal stabilizer. This started by riveting the rear and forward spars together with they doublers. The elevator attach brackets were also riveted to the rear spar.

Now it was time to build up each side of the stabilizer. The process was the same on both sides, so I’ll only explain it once. After the spars were ready, the nose ribs were riveted to the skin. This is where the first replacement of a rivet had to happen. The rivet was not set correctly, so it was decided that it was best to remove it and try again. Luckily, no damage was caused, and the rivet was easily replaced.

Next the “intermediate” ribs, which are ribs not attached to a nose rib, were riveted to the front spar. Then the front spar was riveted to the skin and the rest of the ribs were attached to the front spar and the nose ribs. the last step before putting in the rear spar was riveting the ribs to the skin.

Finally the rear spar was attached to the ribs and the skin. The same process was repeated on the other side to complete the second component of the aircraft.

Priming Day

So since I have a large batch of parts ready to prime, it was time to set up the sprayer and get priming. I started out by scuffing up all the parts for the horizontal and vertical stabilizers and the rudder. This will give the primer something to “hold too”.

The primer that I am using for the entire aircraft is Stewart Systems EcoPrime. This is a one part, water based primer. The reason I chose this primer is because it is non-toxic, and being one part, it is an easier process. Being in a neighborhood, it is important to me to be respectful of my neighbors, so being water based and non-toxic was a key factor.

Next, I set up a spray “booth” from the cardboard box that the tail skins were delivered in. This booth helped to contain overspray and provide support for the bar which held the parts.

I was excited to start priming. It was another step forward. The more I primed, the better I got. I was able to work in batches, about an hour each. It took most of the day, but in the end, I was happy with my results.

Horizontal Stabilizer 2

So, in the last post I discussed assembling the skeleton for the horizontal stabilizer. After the skeleton was disassembled and cleaned up, the structure was “rebuilt” inside the skin. The skin is the thin metal sheet that is the outside surface of the airplane. The skin is put into a jig that has a the contour of the horizontal stabilizer cut out. This helps to hold the shape while assembling the structure.

Once the skins are in the jig, I started adding the front ribs (aka nose ribs) to the skin with clecoes. Next, you add the front spar and cleco it to the nose ribs and the skin. You keep building inside the skin. Next up is the main ribs, and finally the rear spar.

After the everything is in place, the holes were match drilled to final sized. The entire process was completed for the left side, then it was disassembled, and the right side was completed the same way.

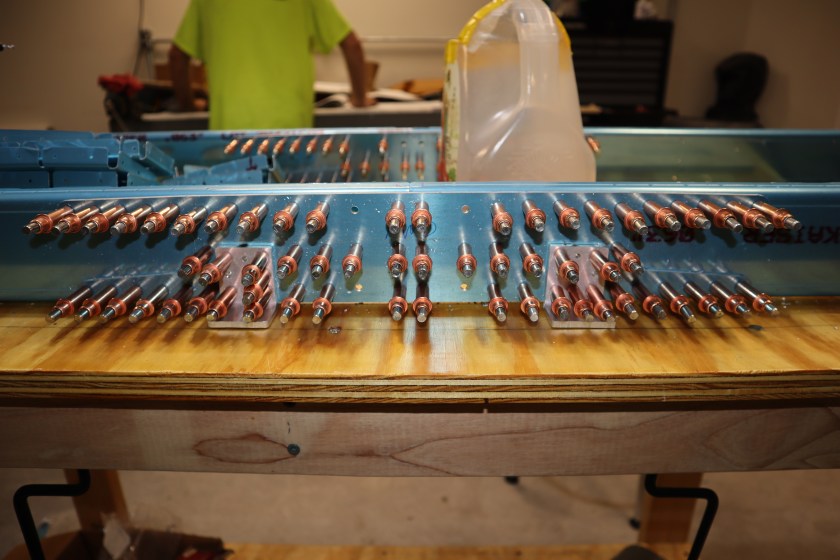

Once both sides were disassembled, it was time to start the final prep of the parts. The skins and ribs had to be dimpled. This refers to putting a small depression into the metal so that a rivet will sit flush once set. This is done with the DRDT-2 and the pneumatic squeezer.

The spars are too think to dimple, so they much be machine countersunk. This is completed by physically removing material with a cutter to create the small depression. The skin dimple will sit inside the machine countersunk depression.

So this is as far as I can go right now. I need to prime the parts, but weather is not cooperating. I will start work on the Vertical Stabilizer next.

Horizontal Stabilizer 1

The build has begun. But before I go into detail, it might be worth explaining some terms that I will use.

The first that comes to mind is “clecoing”. This is temporarily attaching two pieces of metal together using a specialized tool, called a cleco. The cleco is a spring loaded fastener that when compressed, can fit into a certain sized hole, and when uncompressed the cleco clamps the pieces of metal together. This is accomplished to ensure that parts fit properly together.

Another term that will be used is “matched drilled”. The kit came with most holes already drilled on all the parts. Because there could be small differences in parts, it is important to drill through all material to ensure the holes are exactly inline. In addition, most of the pre-punched holes are slightly smaller than the final hole size. To get the hole to the required size for the rivet, a builder mush drill to the final size. This is normally completed at the same time as match drilling.

So, now that we have some terms in place, back to the build. I started by clecoing the front spar doubler to the front spar, then match and final drilling those holes. Following that, two attach brackets were manufactured out of angle aluminum stock.

After those were fabricated, the rear spar doubler and rear spar were clecoed together, then match and final drilled. This was the start to the skeleton of the horizontal stabilizer. Then main ribs, pieces between the front and rear spar, and nose ribs, pieces on the front spar that face forward and shape the front of the stabilizer, were clecoed, matched and final drilled.

Next this structure was disassembled, and new final drilled holes and edges of the parts were cleaned up. Coming up in Part 2, we add a “skin” to the skeleton.