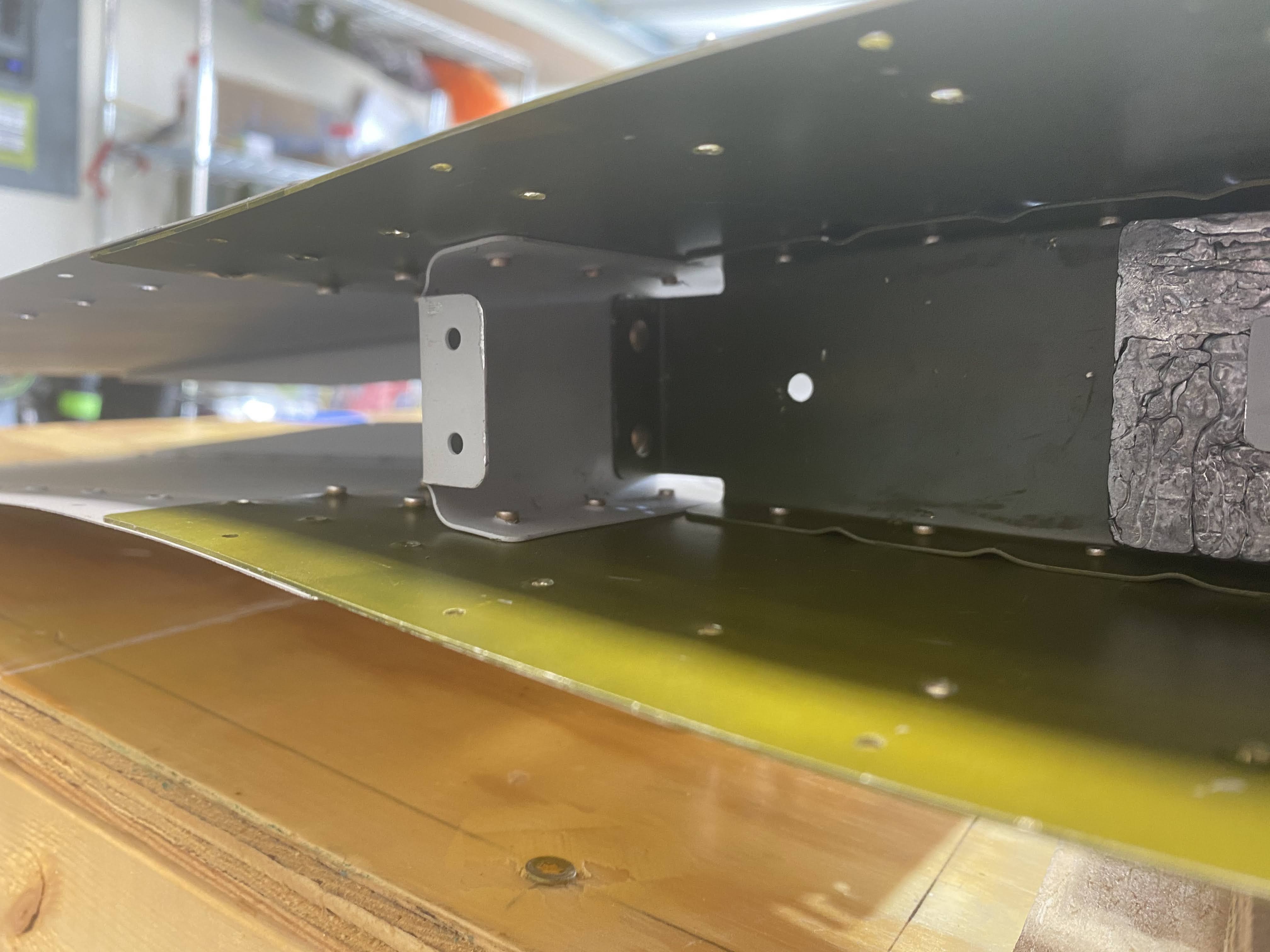

So, the next item up is the trailing edge of the Rudder. This consists of the skins being bonded to wedge and then riveted together. Both skins are dimpled to get a smooth finish, so the wedge has to be countersunk on both sides. This was a new technique for me, but after a little practice, I got the hang of it.

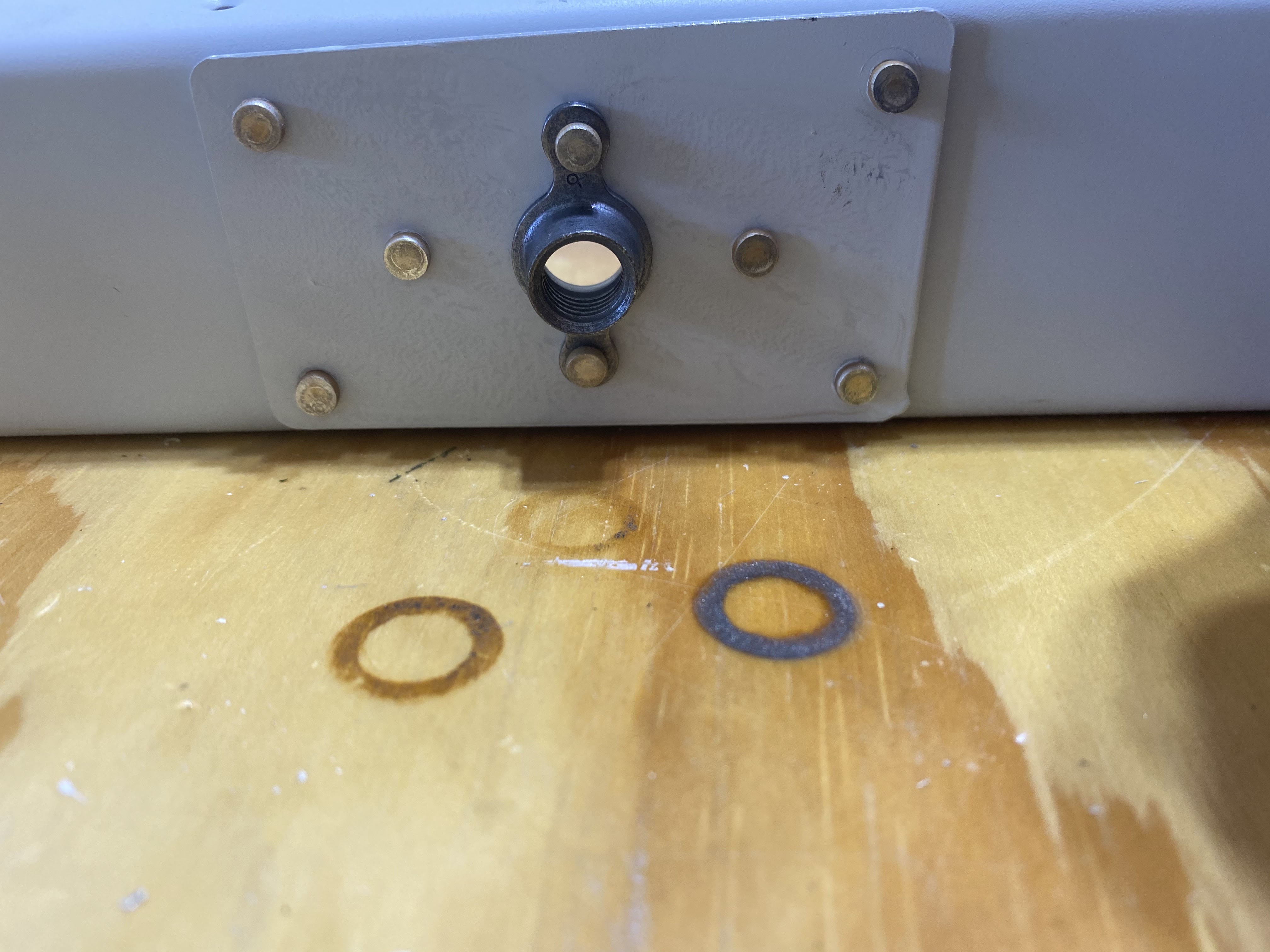

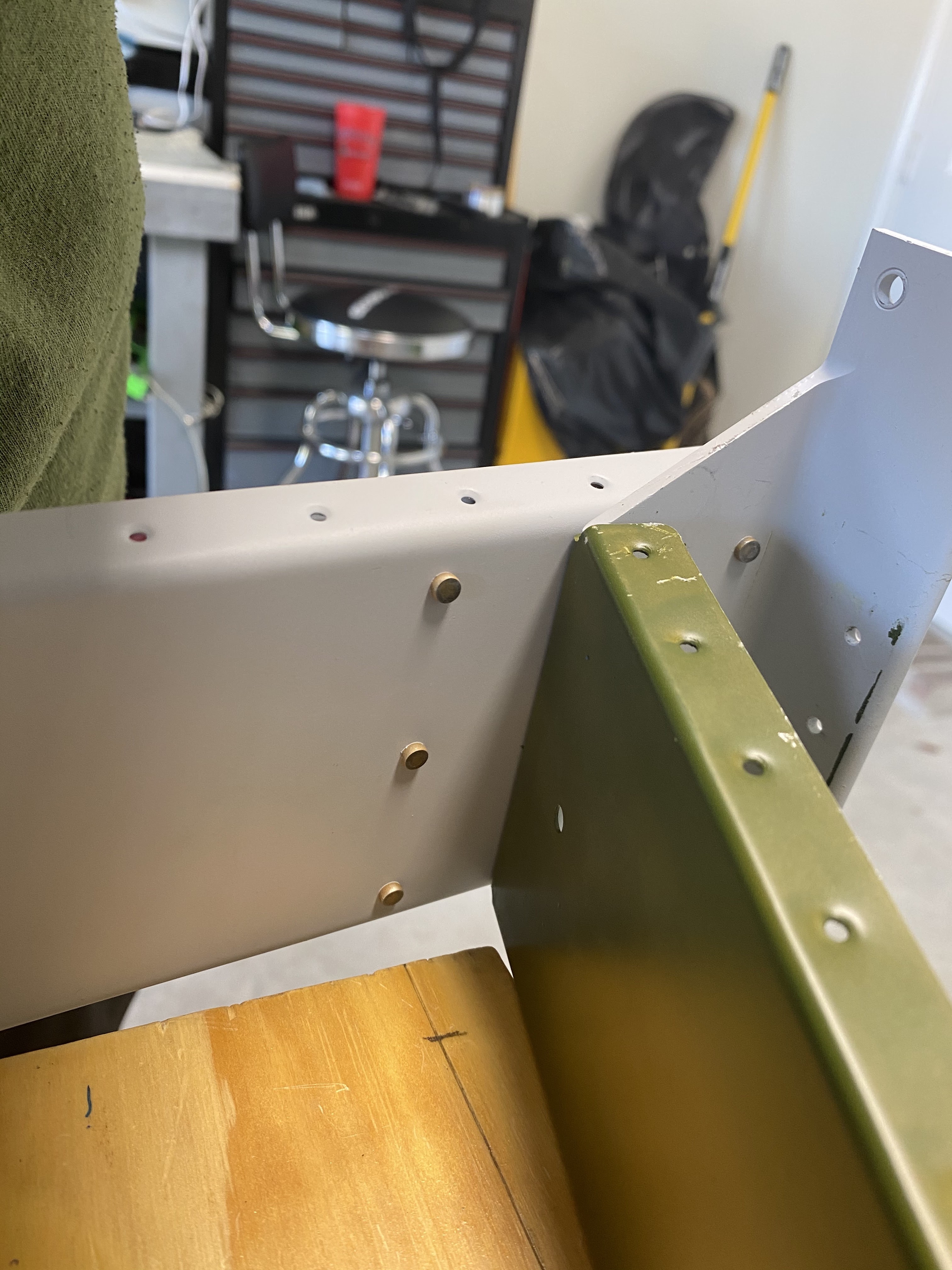

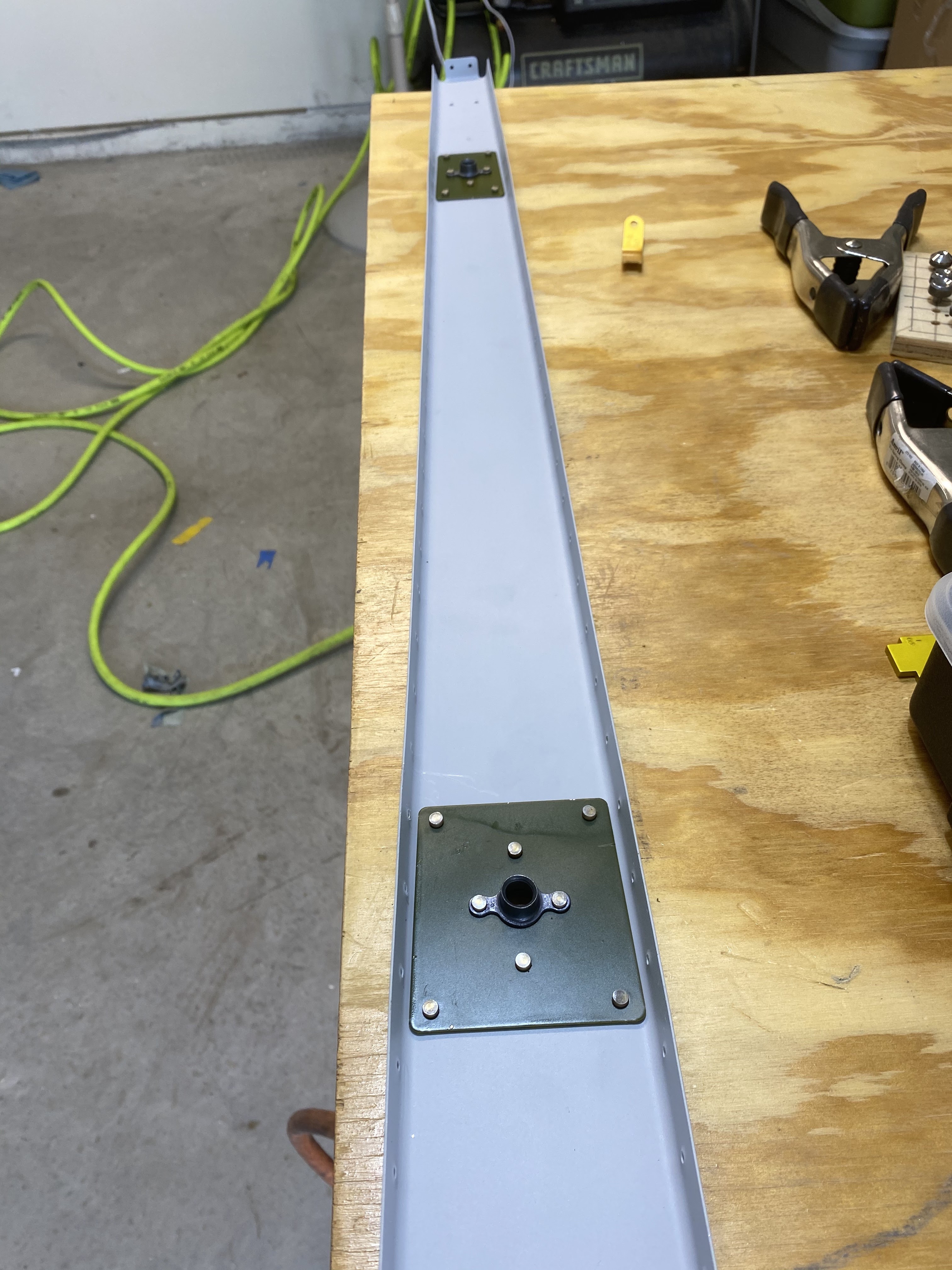

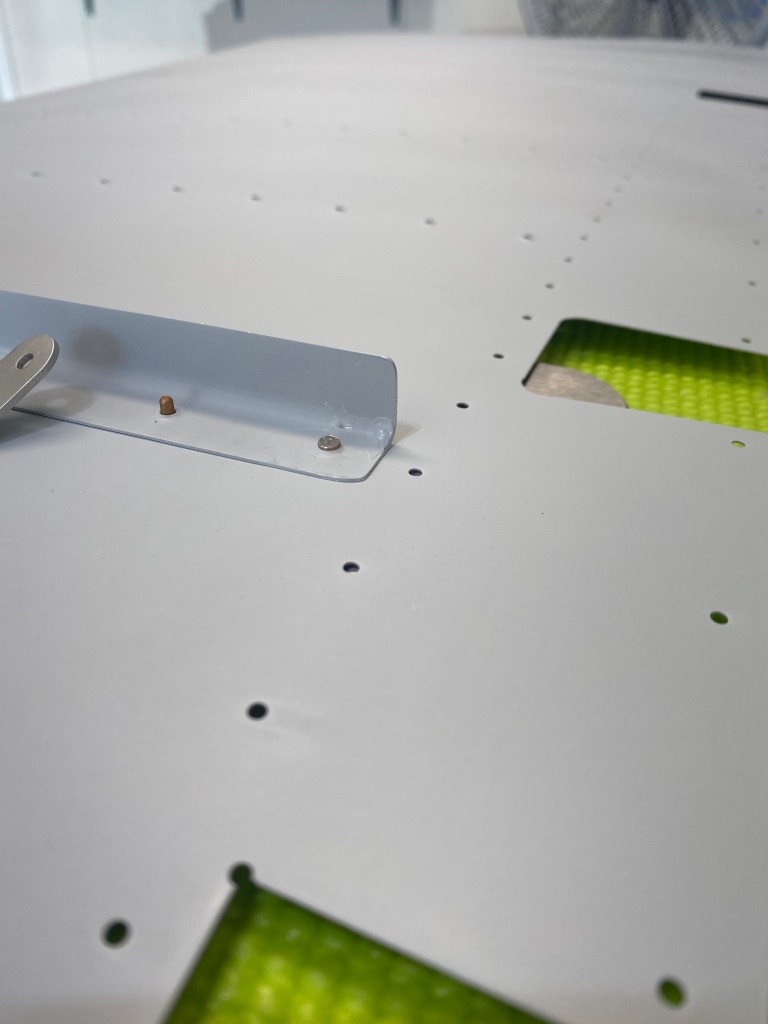

Next up, the wedge is placed between the skins, and bonded using a two part sealant. The edge is then attached to a piece of angled aluminum. This helps to set the trailing edge straight.

After letting the sealant set for a few days, you then rivet the trailing edge together. Overall, I’m very happy with the trailing edge. Only thing left is to roll the leading edge.

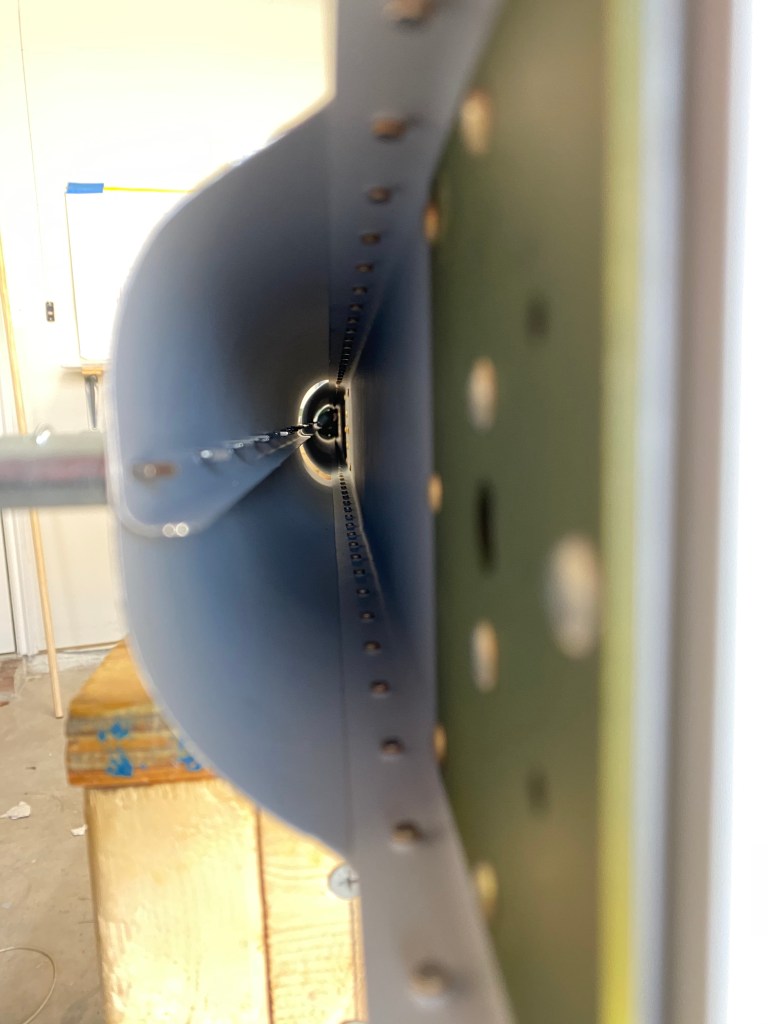

The last item to complete for the rudder is the roll the leading edge. This was not as difficult as I had thought. You get a one inch diameter dowel rod, tape it to the skin, and then roll the skin. It took a surprising amount of force, but I got it bent. Then I match drilled the holes, demurred them, and then pop riveted them together. This marks the completion of the rudder (until I do the fiberglass tips.).