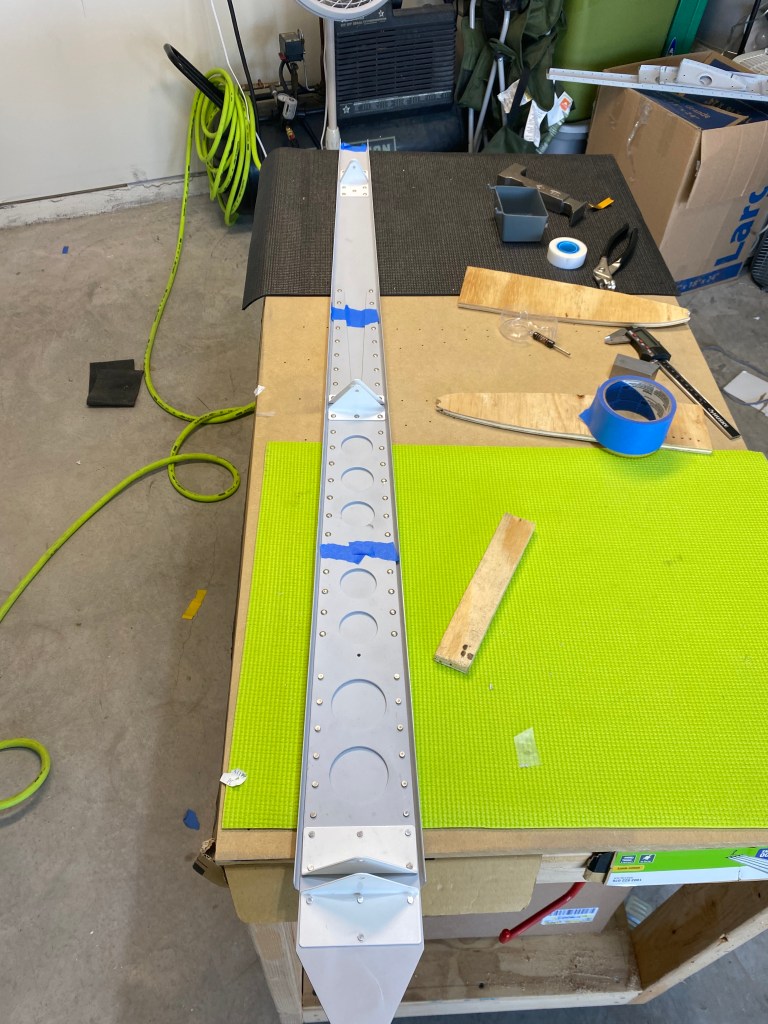

Just a quick picture of the horizontal and vertical stabilizers together before they were put into storage.

Category: Vertical Stabilizer

Vertical Stabilizer 2

Now that the parts were primed, it was time to start riveting the vertical stabilizer together. This started with riveting the rear spar and spar doubler together. The Rudder attach brackets were riveted as well. Once the rear spar was riveted, the ribs were attached and the skeleton of the vertical stabilizer was riveted together to the front spar.

Next the skin was placed over this skeleton, and the skin was riveted to the ribs and front spar. Finally the rear spar was riveted to the ribs and skin. This completed the first major component of the airplane build.

Priming Day

So since I have a large batch of parts ready to prime, it was time to set up the sprayer and get priming. I started out by scuffing up all the parts for the horizontal and vertical stabilizers and the rudder. This will give the primer something to “hold too”.

The primer that I am using for the entire aircraft is Stewart Systems EcoPrime. This is a one part, water based primer. The reason I chose this primer is because it is non-toxic, and being one part, it is an easier process. Being in a neighborhood, it is important to me to be respectful of my neighbors, so being water based and non-toxic was a key factor.

Next, I set up a spray “booth” from the cardboard box that the tail skins were delivered in. This booth helped to contain overspray and provide support for the bar which held the parts.

I was excited to start priming. It was another step forward. The more I primed, the better I got. I was able to work in batches, about an hour each. It took most of the day, but in the end, I was happy with my results.

Vertical Stabilizer 1

Since I have to wait on priming the Horizontal Stabilizer (Horz. Stab.), I started to work on the Vertical Stabilizer (Vert. Stab.). The process is very similar to Horz. Stab. I started by clecoing the spar doubler to the rear spar. Next the rest of the assembly (ribs and front spar) are clecoed in place. Next all holes are match drilled to final size. This creates the skeleton of the Vert. Stab..

Just like before, the skin is then attached to the skeleton. After everything is clecoed together, the skin is match drilled to final size with the ribs and spars. Moments like this when an assembly is together is a very gratifying feeling. It’s a feeling of accomplishment and noticeable change. But this feeling is short lived, because you take it all apart and debur, dimple, and machine countersink the parts. Then it is ready for primer.