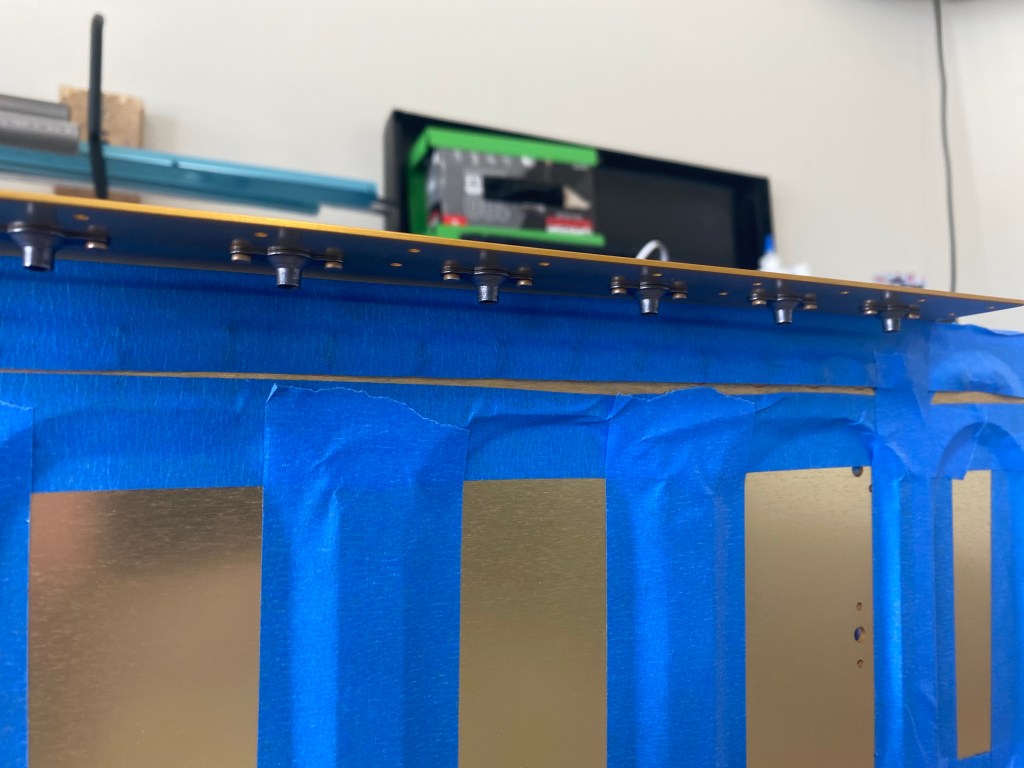

So, now that we have the structure together and the skins on the it, the time has come to fit the fuel tanks and the leading edges. This is the first time that I really got an understanding for how the wing will look and the size. I was surprised. The first step was to attach the leading edge to the spar. this is done by attaching the ribs of the leading edge to the web of the spar (photo one below). Once in place and secured, a splice strip allows the tank to be screwed into it. This means the tank will be screwed into the leading edge.

After leading edge was on, the tank is fitted. It is secured to the spar. Below are pictures of the left wing with both the tank and leading edges on. Big accomplishment.

One big factor is how well these two parts line up. They are both made off the wing, and at this point, it would be very difficult to change the shape. Luckily, both the left and the right sets line up very closely, and I deemed it acceptable.

The last little step in attaching the tank for fit, is to drill the attach holes into the “Z” attach brackets. Since you want these to fit perfectly, the center (of three) holes is drilled before going on the spar, but once there the other two are matched drilled. This ensures a perfect fit. Next up will be more fuel tank work!